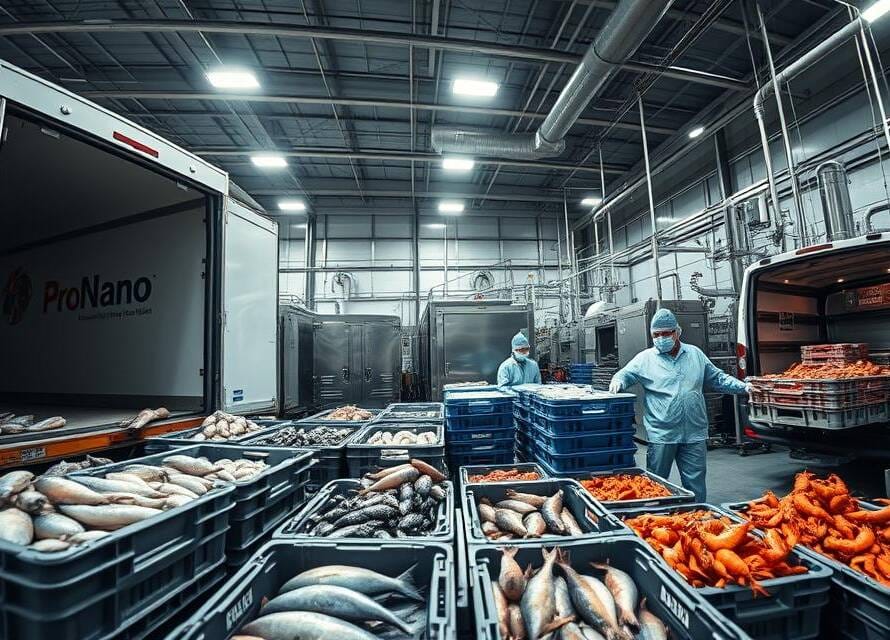

Investing in a Frozen Fish Factory for instant meals is a smart move. The global demand for easy, healthy, and ready-to-eat food is rising rapidly, making this a highly profitable venture. At ProNano, we specialize in guiding investors and entrepreneurs in setting up a Frozen Fish Factory, from the initial planning stages to the moment it becomes fully operational.

The global frozen seafood market is projected to grow with a 5.4% CAGR from 2025 to 2034. This growth is fueled by consumer demand for meals that are ready to eat, nutritious, and convenient. Our team at ProNano brings expertise in food technology, project management, and seafood industry operations to ensure that your Frozen Fish Factory meets both quality and profitability goals.

Partnering with ProNano allows investors to tap into the booming market for ready-to-eat seafood products worldwide. This includes not only traditional frozen fish but also innovative seafood meal solutions designed for modern consumers.

Key Takeaways

Setting up a Frozen Fish Factory requires detailed planning and strategic execution.

The global frozen seafood market is growing rapidly, creating investment opportunities.

ProNano provides expert guidance from concept to operational readiness.

Ready-to-eat seafood products represent a high-growth, high-profit segment.

Leveraging ProNano’s experience ensures your Frozen Fish Factory thrives sustainably.

The Growing Market for Frozen Fish and Ready-to-Eat Seafood in Saudi Arabia

Consumer preferences are shifting globally and in Saudi Arabia, driving increased demand for convenient, healthy seafood products. The Saudi seafood market is expanding due to population growth, rising income levels, and greater awareness of seafood’s nutritional benefits. This makes Saudi Arabia a strategic focus for any Frozen Fish Factory investment.

Current Market Trends and Consumer Preferences

In Saudi Arabia, there is a clear move toward convenient seafood solutions. Consumers increasingly prefer frozen seafood because of its long shelf life and ease of storage. Additionally, ready-to-eat seafood meals that can be quickly prepared at home are gaining popularity among busy households.

Growth Projections for the Saudi Seafood Industry

The Saudi seafood industry is poised for significant growth. Factors driving this expansion include increasing consumer demand, government initiatives supporting local fishing, and investments in seafood processing technologies. The Frozen Fish Factory segment is expected to grow steadily as the demand for fast, convenient seafood meals continues to rise.

Competitive Landscape and Market Opportunities

Competition in the Saudi seafood market is intensifying, with both local and international companies seeking market share. Despite this, opportunities remain for new entrants, especially those offering innovative products and efficient supply chains. Companies capable of advanced seafood processing and distribution are well-positioned to benefit from the growing demand for both traditional frozen fish and ready-to-eat seafood products.

| Market Segment | Current Trends | Growth Projections |

|---|---|---|

| Frozen Seafood | Increasing demand for convenient meal options | Steady growth rate |

| Ready-to-Eat Seafood | Rising popularity of easy-to-prepare meals | High growth potential |

Essential Planning Steps for Your Frozen Fish Factory

Starting a Frozen Fish Factory in Saudi Arabia requires meticulous planning and strategic execution. At ProNano, we guide you through the essential steps to ensure your venture succeeds in the competitive seafood market.

Market Research and Feasibility Study

Conducting market research is crucial for understanding consumer preferences, industry trends, and potential challenges. A detailed feasibility study evaluates demand, supply chain logistics, financial viability, and operational considerations. This analysis helps identify risks and opportunities, providing a solid foundation for your Frozen Fish Factory.

Location Selection and Regulatory Requirements in Saudi Arabia

Choosing the optimal location for your Frozen Fish Factory is vital. Proximity to ports, transportation networks, and suppliers can significantly reduce costs and improve efficiency. Compliance with Saudi Arabia’s regulatory framework—including permits, food safety standards, and environmental regulations—is mandatory. ProNano assists clients in navigating these requirements smoothly.

Creating a Comprehensive Business Plan

A robust business plan serves as the blueprint for your Frozen Fish Factory. It outlines operational strategy, financial projections, marketing plans, and management structures. ProNano specializes in crafting business plans focused on sustainable seafood processing and innovative seafood product development, ensuring your factory is well-prepared for success.

By following these strategic steps, investors and entrepreneurs can establish a thriving Frozen Fish Factory that meets growing consumer demand in Saudi Arabia and globally.

Designing an Efficient Frozen Fish Processing Facility

Designing an Efficient Frozen Fish Processing Facility

An efficiently designed facility is critical for operational success in a Frozen Fish Factory. High-quality production, reduced costs, and smooth workflow are essential for maintaining product standards and profitability.

Optimal Facility Layout and Space Requirements

Efficient layout planning enhances productivity in your Frozen Fish Factory. Key considerations include:

Segregated areas for receiving, processing, and packaging to prevent cross-contamination.

Adequate storage for raw materials, finished goods, and packaging materials.

Streamlined workflow to minimize handling and maximize efficiency.

Temperature Control and Cold Chain Management

Maintaining proper temperature is crucial for preserving the quality and safety of frozen seafood. ProNano implements advanced cold chain management systems to ensure products remain at the correct temperature throughout processing, storage, and distribution.

Utility Requirements and Energy Efficiency Considerations

Optimizing utilities—electricity, water, and gas—is vital for cost reduction and sustainability. ProNano integrates energy-efficient solutions to minimize waste while maintaining operational effectiveness in your Frozen Fish Factory.

By addressing these core areas, ProNano ensures your facility meets global standards for quality, efficiency, and sustainability in seafood processing.

Critical Equipment for Frozen Fish Processing and Ready-to-Eat Seafood Products

Selecting the right equipment is fundamental to running a high-performing Frozen Fish Factory. The choice of technology directly affects product quality, efficiency, and compliance with safety standards.

Fish Processing Equipment Selection

Advanced equipment ensures consistent quality and streamlined production. Essential components include:

Cleaning and Filleting Systems: High-performance filleting machines improve yield and reduce labor costs.

Freezing and Packaging Technology: IQF (Individual Quick Freezing) preserves freshness and texture.

Quality Testing Equipment: Continuous quality control ensures compliance with safety standards.

Ready-to-Eat Meal Production Lines

For ready-to-eat seafood, specialized production lines are required:

Cooking and Preparation Equipment: Industrial steamers and ovens enable efficient meal production.

Packaging and Sealing Systems: MAP (Modified Atmosphere Packaging) extends shelf life.

Shelf-Life Extension Technology: Vacuum packaging and pasteurization further enhance product durability.

Automation and Industry 4.0 Integration

Integrating automation and Industry 4.0 technologies in your Frozen Fish Factory boosts efficiency, reduces labor costs, and enables real-time monitoring. ProNano provides solutions that make facilities globally competitive and ready for innovative seafood product lines.

Developing Your Seafood Product Portfolio

A diverse and innovative product portfolio is critical for success in both the global and Saudi markets. ProNano helps develop offerings that include traditional frozen fish and modern ready-to-eat seafood meals.

Traditional Frozen Fish Products

Popular products in Saudi Arabia and globally include frozen fillets, steaks, and whole fish. ProNano ensures sustainable sourcing and high-quality processing, appealing to environmentally conscious consumers.

Innovative Ready-to-Eat Seafood Meal Concepts

Innovation is essential to meet modern consumer needs:

Quick-Preparation Fish Meals: Easy-to-cook meals for busy households.

Seafood-Based Convenience Foods: Healthy, ready-to-cook fish burgers and nuggets.

Premium Ready Meals: Gourmet seafood options for an upscale dining experience at home.

Packaging Design and Shelf Appeal

Effective packaging enhances shelf presence and preserves freshness. ProNano emphasizes clear labeling, sustainable materials, and appealing design to differentiate your Frozen Fish Factory products in competitive retail environments.

| Product Category | Key Features | Consumer Benefits |

|---|---|---|

| Traditional Frozen Fish | High-quality, sustainable | Freshness, eco-friendly |

| Ready-to-Eat Seafood Meals | Convenient, fast preparation | Time-saving, easy meals |

| Premium Seafood Ready Meals | Gourmet ingredients | Premium dining at home |

Quality Assurance and Food Safety Protocols

ProNano prioritizes quality and safety in all Frozen Fish Factory operations. We help implement HACCP, ISO standards, and Saudi Food and Drug Authority compliance.

HACCP & ISO Implementation: Hazard analysis, critical control points, and systematic monitoring.

SFDA Compliance: Guidance on all regulations ensures safe, legally compliant products.

Testing & Monitoring: Microbiological, chemical, and physical testing maintains top-quality standards.

Building an Efficient Supply Chain

A robust supply chain ensures freshness and operational efficiency. ProNano assists with sourcing, cold chain logistics, and inventory management for your Frozen Fish Factory.

Sourcing Fresh Fish: Local or international sourcing for variety and quality.

Cold Chain Logistics: State-of-the-art refrigeration and distribution systems.

Inventory Management: Just-in-time systems to reduce waste and optimize profits.

Marketing and Sales Strategies for Frozen Seafood Products

Effective marketing is essential to grow your Frozen Fish Factory presence globally and in Saudi Arabia. ProNano helps with:

Retail Distribution: Supermarkets, hypermarkets, and optimized shelf placement.

Foodservice & Institutional Markets: Customized offerings for restaurants, hotels, and institutions.

Digital Marketing & E-Commerce: Online campaigns, engaging content, and user-friendly platforms.

ProNano’s Expert Approach to Seafood Factory Development

ProNano combines food technology, industrial design, and project management to optimize seafood operations.

Food Technology Expertise: Advanced processing for quality and efficiency.

Industrial Design: Smart facility layouts reduce costs and boost productivity.

Comprehensive Project Management: From concept to operation, ensuring timely and on-budget delivery.

Conclusion: Launching Your Successful Frozen Fish Enterprise with ProNano

Starting a Frozen Fish Factory requires careful planning, regulatory knowledge, and market insight. ProNano guides you through facility design, equipment selection, product innovation, and marketing strategies.

Our expertise ensures your Frozen Fish Factory is competitive, sustainable, and ready to capture global and Saudi market opportunities.

FAQ

Q: Key factors for establishing a Frozen Fish Factory with instant meals?

A: Market research, location, regulatory compliance, facility design, equipment, and supply chain management are critical.

Q: How to ensure seafood quality and safety?

A: Implement HACCP, ISO standards, SFDA compliance, and testing systems.

Q: Current market trends?

A: Rising demand for ready-to-eat, healthy, convenient seafood globally and in Saudi Arabia.

Q: Optimizing facility layout and operations?

A: Efficient design, workflow planning, temperature control, and energy efficiency are key.

Q: Benefits of automation and Industry 4.0?

A: Higher efficiency, consistent quality, lower labor costs, and real-time monitoring.

Q: Developing a compelling seafood portfolio?

A: Combine traditional frozen fish with innovative ready-to-eat seafood meals and appealing packaging.

Q: Building an efficient supply chain?

A: Reliable suppliers, cold chain logistics, and inventory optimization ensure operational success.

Q: Marketing and sales strategies?

A: Retail, foodservice, and digital marketing channels maximize reach and sales.

Q: ProNano’s expertise?

A: Food technology, industrial design, and full project management ensure efficient and successful Frozen Fish Factory development.

If you are interested in investing in a Frozen Fish Factory or developing Ready-to-Eat Seafood products, get expert guidance from equipment selection to production optimization to succeed in this growing seafood sector. Contact us for tailored consultations to meet your goals.

Read more about Seafood Processing Technologies