The cheese and dairy industry is one of the basic food industries that plays an important role in meeting the needs of consumer, vitamins and minerals necessary.

Therefore, establishing a cheese and dairy factory is a promising project and is able to achieve great profits, especially if it is planned and implemented properly.

In this article, we will review everything related to the manufacture of cheese and milk, including manufacturing steps, production lines, and the most important things that must be taken into account to ensure the success of the project.

The basics of cheese and dairy industry

Basic raw materials

The establishment of a cheese and milk factory depends on basic raw materials that must be provided to ensure the quality of the final product. Among the most important of these materials:

Milk: Milk is considered the primary raw material in the manufacture of cheese and milk. Cow’s milk, sheep, or goats can be used according to the target product.

The reinforcement: The rennet is used to stimulate the virginity of milk and turn it into cheese.

Mbeta bacteria: Helps develop taste and textures for different cheese.

Salt: It is used in salting to improve the taste and increase the period of cheese validity.

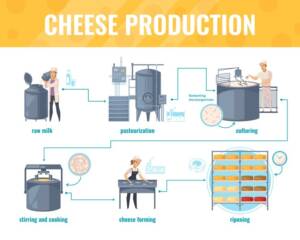

Cheese production stages

The process of manufacturing cheese passes through several basic stages, which differ slightly depending on the type of cheese to be produced:

Milk collection and processing: Milk is collected from local farms and is subject to a jacket to kill harmful bacteria.

Add the joys and lactic bacteria: Add the reinforcement and bacteria to the milk to start the clotting process.

Cut the thrombus: After the milk is thrombosis, the thrombus is cut into small pieces to facilitate the process of separating the sprinkle (when).

Separation of the spice: The sprinkler is removed from the thrombus, and this affects the final consistency of the cheese.

Forming and salting: The thrombosis is formed according to the desired type of cheese, then it is salted to enhance the taste and keep cheese.

Steeling: Some cheeses require a period of gathering ranging from weeks to several months to get the ideal taste and texture

Dairy production stages

The dairy industry depends on a group of productive lines that help in manufacturing various products such as pasteurized milk, yogurt, cream, and butter. These lines include:

Pasteurized milk production line: It includes filtering, pasteurization, and packing in bottles or packages.

Yogurt production line: It starts with the milk pasteurization, then add the milk bacteria, followed by fermentation, then packing.

Butter production line: The butter is manufactured by whisk the cream to collect fats, then knead and pack it.

The cream production line: It requires the separation of milk into cream and detection using milk storage, then processing cream.

Challenges to establish a cheese and dairy factory

Technical challenges

The establishment of a highly accurate cheese and milk factory in productive processes and the use of advanced techniques to ensure the quality of the final product. From these challenges:

Temperature control: specific temperatures must be maintained during the various manufacturing stages, such as pasteurization and clotting, to ensure the quality of the product.

Control of the acidity level: The acidity level plays a big role in determining the type and quality of cheese.

Waste management: The waste resulting from the manufacturing process, such as the spray, should be managed in a way that ensures the preservation of the environment.

Tips to ensure the success of the project to establish a cheese and dairy factory

Research and planning

Before starting the establishment of a cheese and dairy factory, it is necessary to conduct a comprehensive research on the local market and understand the needs of consumer. Good planning contributes to determining the appropriate production volume and determining the best types of cheeses and dairy that are appropriate to the market needs.

Investment in technology

Modern technology is an essential component of the founding of the cheese and dairy factory. You should invest in modern equipment that helps improve efficiency and product quality, such as automatic pasteurization and fermentation machines.

Training and development

Labor training in the use of modern equipment and technologies is vital to ensuring the workflow and producing high -quality products. It is also useful to follow the latest developments in the manufacture of cheese and dairy and apply best practices.

Secondary products in the cheese and dairy factory

whey

During the process of manufacturing cheese, the whey is produced as a secondary material. The spray products industry is a growing industry, as it is used in the production of energy drinks, nutritional supplements, and some other dairy products. The chip contains a high percentage of proteins and vitamins, which makes it a valuable nutrient.

Industry of butter and cream

Besides cheese, the production of butter and cream is one of the important related industries. Film milk can be converted into high -quality butter and cream through advanced separation processes. These products are widely used in cooking, bread, and desserts, which make them of high market value.

Milk and yogurt industry

Milk and yogurt is one of the sub -dairy products that are very popular. List bacteria are used to convert milk into yogurt through a fermentation process that enhances its health benefits. This sector is experiencing increasing growth due to the increase in consumer awareness of the health benefits of yogurt and fermented products.

Flavors and food additions in the cheese and dairy factory

Natural and industrial flavors

Flavors play a big role in improving and developing cheese and dairy products. Flavors are used to give a distinctive taste to products such as yogurt, flavored milk, and flavored cheese. Flavors can be normal, such as fruits, or industrial, and are added thoughtful to enhance the consumer experience.

Preserving materials and stabilizers

In order to increase the validity period of cheese and dairy products, preservatives and stabilizers are used. These materials contribute to maintaining taste and textures for a longer period, and also help prevent bacteria and fungi growth. The types of preservatives vary depending on the type of product and health standards required in the targeted markets.

The establishment of a cheese and dairy factory is a sedimentary project that can achieve large returns if it is properly implemented. By following best practices in manufacturing, investing in technology, and ensuring the quality of raw materials, the new factory can prove its presence in the market and contribute to meeting the increasing demand for high -quality dairy and cheese products.

ProNano Food Consulting Company provides full support in all stages of establishing a cheese and dairy factory, starting with the design line design, to cadres training and quality management. The company is also distinguished by providing innovative solutions specifically designed to meet the needs of its customers, taking into account environmental standards and modern market directions.

Contact us if you want to turn your vision into a successful and sustainable reality in the world of cheese and dairy industry

2 Comments

BonusBacklinks

Generally I do not learn post on blogs, however I wish to say that this write-up very forced me to check out and do so! Your writing style has been amazed me. Thank you, quite great post.

BonusBacklinks

I like this web site very much so much excellent info .